Breaking Borders: Finding Performance with Concrete Crusher for Sale

Breaking Borders: Finding Performance with Concrete Crusher for Sale

Blog Article

The Ultimate Guide to Selecting the Right Concrete Crusher for Your Recycling Requirements

Picking the best concrete crusher for your recycling demands is a crucial choice that needs careful factor to consider. By the end of this overview, you will certainly have a comprehensive understanding of just how to choose the perfect concrete crusher that will maximize your reusing efforts.

Factors to Consider

When picking the right concrete crusher, there are numerous important aspects to consider. Different crushers are made to deal with various kinds of concrete, such as reinforced concrete, asphalt concrete, or combined concrete.

Another element to take into consideration is the desired outcome dimension of the crushed concrete. The size of the result product will figure out the sort of crusher that is most suitable for the task. Some crushers are made to produce fine fragments, while others are much better suited for rugged squashing. It is very important to match the crusher's capabilities with your desired output size to make sure optimum performance.

Furthermore, the manufacturing ability of the crusher is an important consideration. The amount of concrete waste you require to refine will certainly figure out the needed manufacturing ability of the crusher. It is essential to choose a crusher that can deal with the expected volume of concrete waste without causing any delays or inefficiencies in the recycling process.

Lastly, the cost and maintenance needs of the crusher must be thought about. It is essential to spend in a crusher that supplies a good balance in between price and performance. concrete crusher for sale. Additionally, consider the maintenance needs and schedule of extra parts to guarantee smooth operation and minimize downtime

Kinds Of Concrete Crushers

When selecting the best concrete crusher is understanding the numerous types available in the market,One critical element to consider. The kind of concrete crusher you select will rely on elements such as the kind, dimension, and location of the concrete waste you require to process. Below are a few of the most typical sorts of concrete crushers:

Jaw Crushers: These crushers are made to crush products with high compressive stamina, such as concrete and enhanced concrete. They are frequently used in the main stage of concrete reusing procedures.

Cone Crushers: Cone crushers are used for additional squashing in concrete recycling procedures. They resemble gyratory crushers yet have a various squashing chamber design. Cone crushers appropriate for processing concrete with intermediate to high solidity.

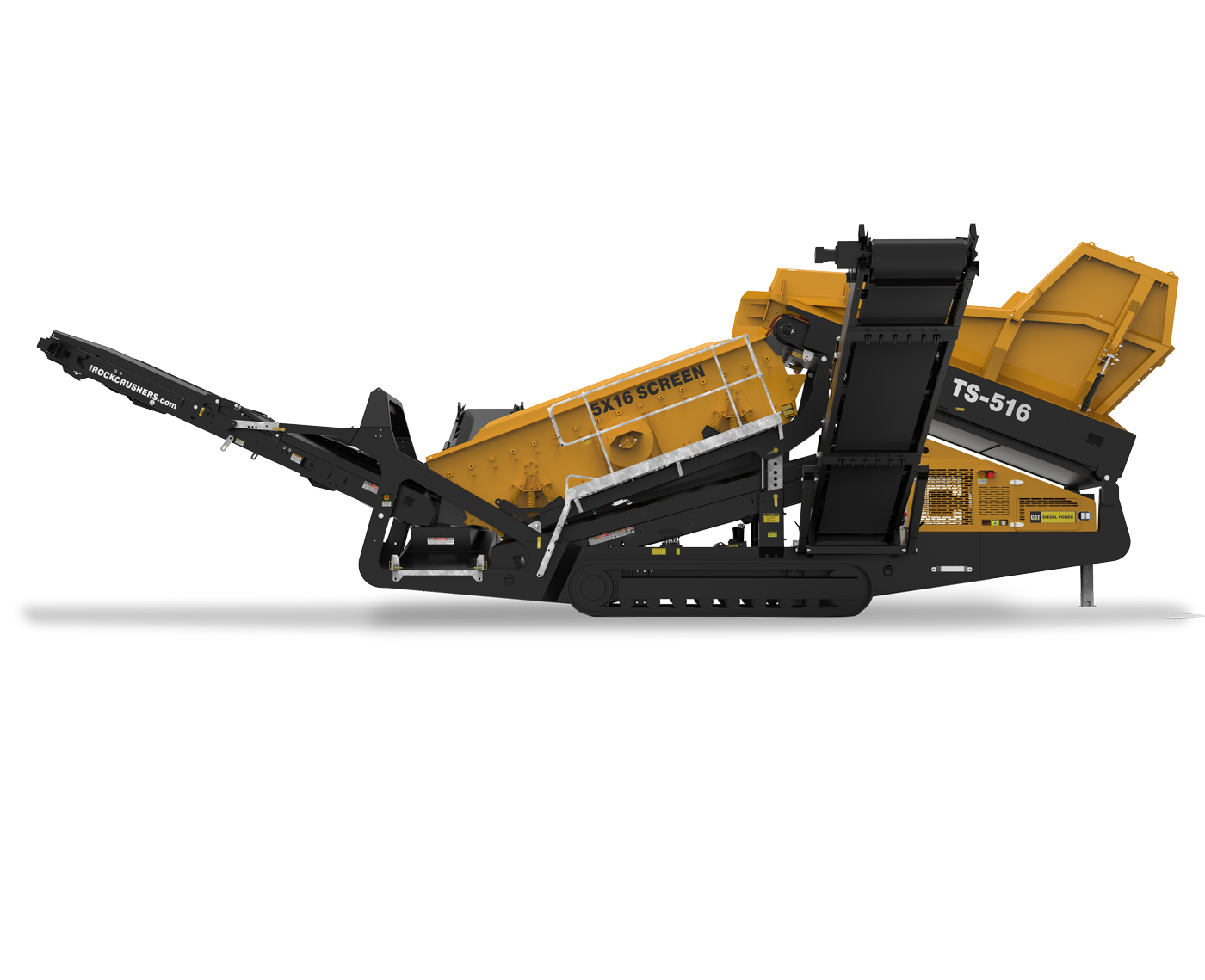

Mobile Crushers: Mobile crushers are made to be carried to the site and can be run on-site. They are flexible and can process concrete waste in different places.

Comprehending the different types of concrete crushers offered in the marketplace will help you select the right one for your reusing requirements. It is very important to consider variables such as the sort of waste, desired output size, and movement demands when making your decision.

Understanding Capability Requirements

To figure out the proper capability for your concrete crusher, it is necessary to assess the volume and regularity of concrete waste you require to refine. Understanding your ability demands will certainly assist guarantee that the crusher you select can efficiently deal with the amount of concrete waste you generate often.

First, consider the quantity of concrete waste that you require to process. This can be identified by analyzing the size and scope of your tasks, along with the quantity of concrete waste produced during each task. If you have large building jobs that generate a substantial quantity of concrete waste, you will likely need a crusher with a higher ability to manage the volume efficiently.

Following, examine the frequency at which you generate concrete waste. If you have a continual circulation of concrete waste, such as in a commercial construction setup, you may need a crusher with a greater capability to handle the consistent influx of top article waste. On the various other hand, if you produce concrete waste occasionally or in smaller amounts, a crusher with a lower ability might be sufficient for your demands.

Examining Movement Options

When picking the best concrete crusher for your demands,Thinking about the mobility choices readily available is important. The capability to relocate the crusher around the building website is necessary for efficient and reliable recycling operations. There are numerous movement alternatives to review, including track-mounted, wheel-mounted, and stationary crushers.

Wheel-mounted crushers, on the other hand, are mounted on wheels or tires, giving better mobility compared to stationary crushers (concrete crusher for sale). They can be quickly moved to various locations using a truck or trailer. Wheel-mounted crushers are appropriate for smaller sized building and construction websites or tasks that require occasional relocation

Stationary crushers, as the name suggests, are repaired in one location and can not be quickly relocated. They are typically used in permanent recycling facilities or big building sites where wheelchair is not a demand.

When examining wheelchair choices, it is very important to take into consideration the details demands of your job, such as the size of the building site, the frequency of moving, and the surface problems. By very carefully analyzing these variables, you can establish one of the most ideal movement option for your concrete crusher.

Key Attributes to Try To Find

When picking a concrete crusher, it is crucial to meticulously think about the vital features that will certainly best meet your certain needs. It is important to select a crusher that can manage the volume of concrete you require to reuse to prevent any delays or ineffectiveness in your reusing process.

One more trick feature to think about is the dimension and weight of the crusher. In addition, it is essential to look for a crusher with flexible settings, as this allows you to regulate the size of the final item.

In addition, it is essential to think about the power source of the crusher. In addition, it is essential to take site link into consideration the upkeep and utility of the crusher.

Final Thought

To conclude, selecting the best concrete crusher for your reusing demands requires cautious factor to consider of factors such as capability demands and flexibility options. Comprehending the different kinds of concrete crushers available and their key features is critical in making an informed choice. By considering these elements, you can make sure that you select a concrete crusher that meets your particular reusing demands and maximizes effectiveness.

Various crushers are designed to take care of different kinds of concrete, such as reinforced concrete, asphalt concrete, or mixed concrete. The kind of concrete crusher you select will depend on variables such as the kind, size, and area of the concrete waste you need to process. Jaw Crushers: These crushers are made to squash materials with high compressive toughness, such as concrete find this and reinforced concrete.Thinking about the flexibility choices offered is crucial when picking the appropriate concrete crusher for your demands.Wheel-mounted crushers, on the various other hand, are placed on wheels or tires, giving greater flexibility compared to stationary crushers.

Report this page